At the Bench

How does a custom ring actually get made? Here’s a tool-level view of what goes on at our goldsmithing bench after a design has been finalized:

Any gems you bring for repurposing are unset, cleaned and evaluated. We order precious metals and new gems specific to the design.

white gold ring castings, yellow gold wire and bezel strip, loose sapphires in fancy colors and shapes

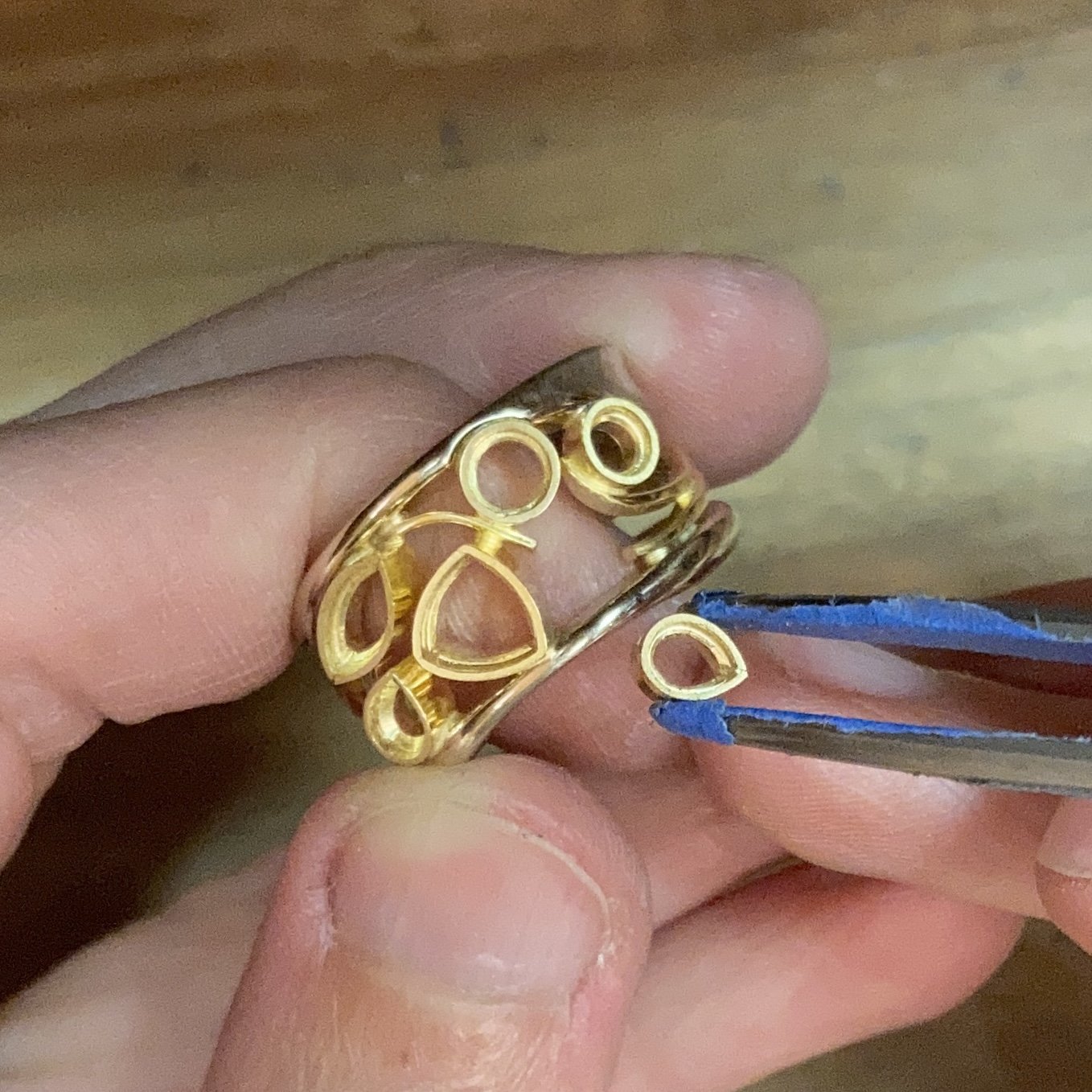

Each component is made by hand from metal strip, wire, or sheet. This is called fabrication.

Here, the individual gems are nonstandard sizes and shapes, so each bezel must be to fit exactly.

Once all of the bezels are made, the elements of the ring are fabricated.

If some parts are carved from wax and cast, the castings are cleaned and polished.

Now the parts are joined together using precious metal solder.

Once all of the assembly is done, we have the client come in to try the ring on before adding the gems. It’s always easier to make adjustments to size without worrying about damaging the gems.

After the fitting, we set the gems in their custom-made bezels. This part is done under a microscope.

We use either pushers or hammer-punches to bend the bezel lip over the stone’s girdle.

A final polish, and she’s ready to go!